1951 Bentley Continental Fastback

The early 1950’s were a sobering time in Britain. The island was left devastated by the war and the commodities and luxuries that were once commonplace were still subject to rationing. Rising taxes combined with frozen wages kept the average person struggling. When gasoline rationing was lifted on May 26th 1950, people began to drive their cars again; however automobile manufacturers were dealing with limited resources and a clientele with less money to buy their products. With the economy improving, business began to improve after the end of gas rationing and The Director of Bentley’s Experimental Department was given a top secret project known as Corniche II to prepare. The goal was to create a fast luxurious two-door, four-seat grand touring vehicle. This special vehicle became the R-Type Continental.

Rolls Royce had bought Bentley Motors in 1931 and had simply rebadged their smallest cars as Bentley’s to keep the marquee alive. Roads were improving and other brands were creating better performing cars, so Rolls-Royce recognized that they would have to further develop their cars to keep them competitive and current. Rolls-Royce asked the Bentley engineers to create a car that could sustain high maximum speed for Continental touring on the long straight roads of Europe. The car had to have excellent acceleration and handling to compliment the high speeds, and the engineers were to find a solution using the Bentley 4 ½ litre car.

The Bentley engineers decided to test one of their 4 ½ Litre cars to the Bristol wind tunnel and they discovered that the car was more efficient running backwards. The engineers learned the exterior shape was inefficient and inhibiting the top speed of the car and a new shape was needed. The big problem was the large grille had the aerodynamics of a brick wall, but it was an intricate part of the brands image. Designers felt that changing the grille would alienate to Bentley’s conservative customer base, so the engineers were told to find a solution to the problem, but first they needed a buyer for the experimental car before starting work. They found an enthusiastic sponsor in Greek shipping magnate André Embiricos who desired the low drag 4 ½ litre coupe.

Bentley commissioned Georges Paulin, who was a dentist by trade and a French Resistance war hero but also a part time automobile designer, to design the new body of the car. Paulin had impressed the engineers with his work on Darl’mat Peugeots, and was considered one of the top French stylists at the time. It has been written that everything that Paulin designed had aerodynamics in mind. He was concerned with fuel efficiencies and aerodynamic efficiencies that could be created by the lines of the car. Paulin believed that aerodynamics allowed you not only to go faster, but be able to use a smaller engine in the car. Paulin penned the shape of the new coupe that was similar to the Talbot Lago, which he had designed earlier. The design included the cowled radiator cover and teardrop shaped fenders with covered wheels to further lower the car’s drag coefficient.

The Bentley engineers modified the 4 ½ Litre motor and produced a lower radiator to accommodate the new design before sending the chassis to Pourtout’s workshop in Paris, who was Paulin’s coach-builder of choice. Pourout’s craftsmen created the body mostly from aluminum to keep the weight down. Even the frames for the seats were constructed of aluminum saving over 100kg on the car. The finished product was a revolutionary streamline design combined with mechanical advancements and light weight coach work to create the world’s first true ‘super car’ forty years before the phrase was created.

The Embiricos Bentley was completed in the summer of 1938 and immediately sent to the Montlhéry track south of Paris for speed testing. The car was reported to have barely topped 100 mph, but it handled well. Embiricos took delivery of the car soon after the test, but he returned the car for further testing. Improvements were made and the car broke a speed record set by a Mercedes Benz. Engineers selected larger wheels and found the car’s speed improved, averaging over 110 mph on a four mile section. Embiricos sold the unique Bentley to HSF Hay in 1939. Hay put over 60,000 miles on the car, before he entered the car in the first post war edition of the 24 hours of Le Mans in 1949, where he came in 6th place. Hay raced the car two more times and placed 14th and 22 nd place in those races with over 120,000 on the car. Hay sold the Embiricos Bentley in 1969 having owned the car for thirty years.

The original reservations about streamline design were partially correct. The car demonstrated superior performance, but the Embircios Bentley was not well received because the styling was clearly too advanced for the average Bentley customer, and no more 4 ½ litre chassis were sent to France for similar treatment.

At the time Rolls Royce management was concerned and divided as to whether the market was ready for such an expensive and high powered vehicle. Once the signal to start development was given, the director of Bentley’s Experimental Department, Chief Project Engineer Ivan Everden began working on the top-secret project in 1950 known as Corniche II. Everden used the Embiricos Bentley as the design to start the development.

In order to achieve the lofty ambitions for the car, extensive research and testing was performed using quarter-scale models at the Hacknail wind tunnel. The extensive testing and alterations allowed Ivan Everden and John Blatchley of the Motor Car Division, to design an aerodynamic body that reduced drag and had excellent stability at speeds in excess of 100 mph. By late summer of 1951, the drawings and scale models had become the prototype R-Type Continental named OLGA after the register index number “OLG 490”. Every effort was made to produce the car with the lightest material available including aluminum bumpers, body panels, window frames and seat backs. Non standard tires were used and radios were only added at customer’s request. The results were that the car was able to reach a quarter mile in 19.5 seconds which was an amazing achievement at this time.

Bentley displayed their new R-Type in 1952 at the Earls Court Motor Show. Bentley said the R-Type was available in a two-door Continental or Saloon. The look of the R-Type Continental was one of the most striking things about it. With raised front wings that swept across the doors, before tucking into the rear of the vehicle, curved windscreen, smooth fastback, and fin-like rear wings all-together made a breathtaking car. The R-Type Continental was the closest Bentley came to adapting Paulin’s aerodynamic ideas, but the Continental and most of its successors continue to retain the large upright “Bentley radiator”, however the Bentley Continental R is still considered one of the most beautiful cars in British automotive history.

Testing of the new Bentley began in September of 1951 in France under the direction of Walter Sleator, who was an ex race car driver and the Rolls Royce agent in Paris. After extensive testing and refinements, production began in early 1952. The Bentley Continental R became the fastest production four-seat car in the world capable of speeds over 100 mph and performance that eclipsed many sports cars of the era. The combination of light weight construction and the sleeker body style resulted in performance that was superior to any Bentley produced after the war. The chassis were assembled in the Crewe factory and sent by rail to the coach builder H.J. Mulliner in Chiswick. All of the Continentals ever produced for Bentley would be coach-built, and therefore, very distinctive. The Fastback featured a steeply descending rear end completed by a boot handle and the Bentley logo. All but 15 of the 208 Bentley Continental’s were fitted with the fastback bodies. The cars were produced between 1952 and 1955 with the A, B, and C, models were fitted with 4.5 litre motors and the D type was fitted with a 4.8 litre motor.

The Bentley Continental R was designed to be driven by the owner-enthusiast and was considered the vehicle for the sportsman who wanted to drive far and fast. Nothing was held back on this car with the top speed of the car was said to be 118 mph, but the controls and steering were heavy, and the fuel consumption was described as ‘fierce’. Testing showed that when the car was driven hard, that it consumed tires at a ‘phenomenal rate’ and it was not stable in wet conditions. The interior was filled with leather, carpet, and wood of the finest quality, but performance was the most important feature of the car. In 1952 the Continental R sold for £7,608 and all of the cars were built for export. The price was part of the appeal and the car was the considered the ultimate automotive status symbol at the time. The Bentley Continental R was an extremely well built car and most have outlived their first owners, and the majority of them are still raced competitively in rallies today.

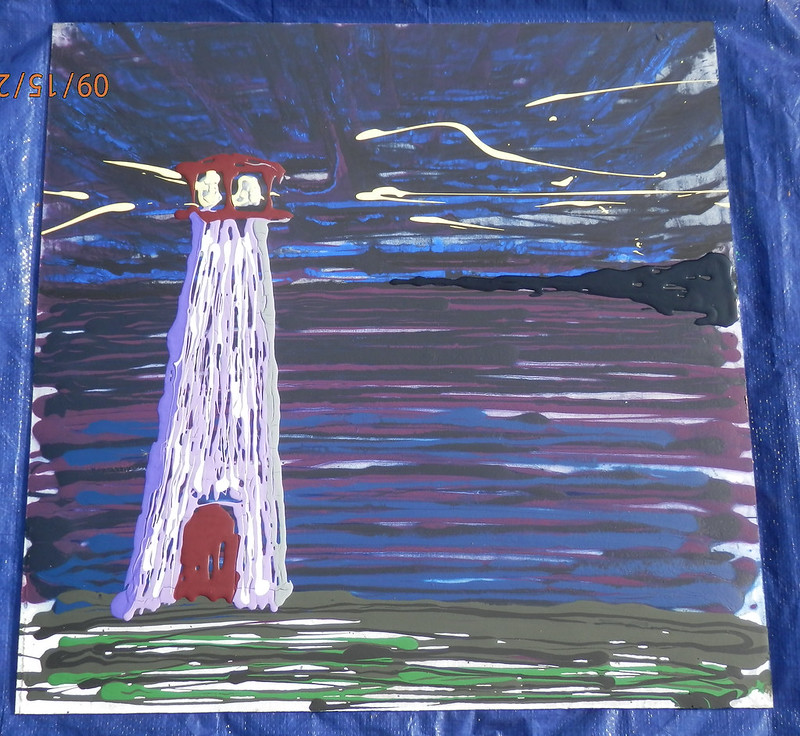

The Bentley Continental is one of my favorite cars of all time. I have loved the use of parallel lines in the body at various places to create the image of a speed. For example, the shape of the front fenders and the hood make a series of gently rounded parallel arcs that are accentuated by the highlight on the side of the fenders that runs down the side of the car leading your eye to the long fin shaped fenders in the rear coming to a point with the intersection of the sloping body that tapers down to the bumper. The peaks on the top of the fenders run parallel to the smaller peaks of the headlight cowls. These parallel lines combined with the sloping shape of the fastback design produce the flowing feeling the car’s image projects. These details caught my eye when I first saw the car in a book over 20 years ago and they are just as powerful today. I tried to carve the Continental when I first began carving cars, but I had not figured out how to put wheels on the cars at that time and the car sits unfinished, but it will be features in the Studs at a later date.

I carved the Bentley Continental as the second car in this series after I had carved the 1930 Nutting-Bodied Speed-Six known as ‘The Blue Train Bentley’. The experience of working with the mahogany wood was helpful in making this car. I thought that the even grained wood would enhance the details of the body of the car and my ideas proved correct. The even tone of the wood with no grain highlights emphasizes the details I carved in the car. I knew that the wood was hard to work with my pocket knife, but the section of the board I used for this car had less cross grain sections than the Bentley Speed Six. The only problems I found were small sections on the fenders, and I had to make sure that the tearing of the grain did not create low spots on the car’s surface. I kept the knife very sharp when working with this project and I was careful to take my time and get the details correct. I highlighted the trim line around the fender and slowly carved back the fender section, allowing the highlight to emerge from the original cut block, but if the wood grain had come out in a section and tore from the car, this detail would have been lost.

I have a motto when cutting out the car shapes from the block that I ruin the cars with the saw and fix them with the pocket knife. I was lucky that I had left this car cut large, meaning that the saw cut outside the marked lines of the pattern and gave me the material to mold the rounded surfaces of the body panels like the hood and roof lines. I had foolishly attempted to cut the fender intersection at the rear slope area with the saw and it left a deep mark on the back of the body of the car that I had to cut out. I have dealt with these deep cuts many times and the saw will gouge the wood and as you cut out the line. The remaining part of the area must be cut down to maintain the shape of the body you are trying to create, so these ‘gouges’ can add distortion to the shape. Luckily I was able to cut out the gouge in the rear of the Continental and maintain the sloping body shape.

Cutting out the rear fenders was another challenging task since the fenders had to be the same width and the area where the fender formed and separated from the body had to be made. The back side of the fender needed to be created to make the slope running down the body to form the fast back. I felt this area was critical to the success of the design, and had to be executed properly. This area was the same area affected by the gouge from the creation of the fenders from the fastback and took special attention to maintain the form. I took a long time working on this piece as I carefully worked out these details and rounded the surfaces of the body to recreate the car as close to the original car as I could create. I took special care carving the front area of the car and creating the inset headlights and the rounded grille. I made the hood ornament with the knife and I had the same problems as the ornament on the Speed Six. The Continental’s hood ornament broke in half as I was started carving it causing panic. I worked with the stump that was left, and I was pleased with the small wing structure that I carved and thought that this design came out better than the Speed Six hood ornament.

I decided to finish the car with the knife marks left in the surface, but since the wood was hard, these marks were very small creating a smooth texture on the surface similar to a sanded surface and they helped highlight the form. I did not want to sand the car because I was afraid that would eliminate the fine details I had worked so hard to carve. The subtle details came alive with the contrast of the smoother wood of the body panels. I finished the car with a hand rubbed bees wax shine to bring out the grain and produce a shine to the wood. The soft brown tones of the wood with few grain highlights emphasized the fine details of the car when in proper lighting.

The Bentley Continental was a benchmark for Bentley created in one of its darkest hours. The car was produced at a time when few resources were available and the management at Rolls Royce had demanded tight time tolerances for the development of the car, but the Bentley engineers not only managed to produce the car within the tight parameters, they produced one of histories truly great automotive classics in the process. I was most excited about carving this car again because of my love of the challenging design and I wanted another attempt to produce this car. My abilities have improved since my last endeavor and I knew that the combination of rich colored wood and the better execution would make this classic car one of the most spectacular of my collection.